|

Joint tester – multi-part

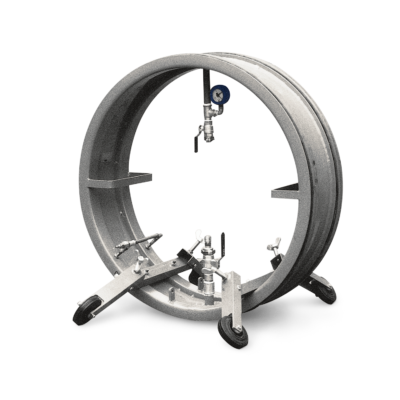

The multi-part joint tester for round profiles includes several parts and allow disassembly of the inspection unit into 2 or 3 components This way, it may also be introduced easily through a manhole. At the installation site, the pipe joint tester requires just a few steps to reassemble. The carriage helps to center the pipe joint tester in the inspection area; the two extra-wide hollow chamber profiles located at both sides of the pipe sleeve are pressurized by means of a foot operated air pump or another generator of pressurized air with a pressure of 4 to 6 bar to seal the test chamber hermetically. In case of a water leakage test, keep the bleeding valve open and fill test chamber with water until water exits from the bleeding valve. Then close the bleeding valve, wait for the indication of the test pressure selected and close the inlet valve as well to start the test. To perform the air pressure test, the test pressure required is generated in the test chamber. |

|

Characteristics

|

Ordering Information

|

Support documents

|

|

Characteristics |

to perform leak tests of round profile pipe connections with air or water acc. to standard EN 1610 and other test standards

the construction in several parts allows an introduction through manholes for later installation on site

it is a rugged welded steelwork of several parts with 2 hollow rubber chamber profiles and undercarriage

including adaptor quick connectors type 26 (tire valve) and adaptor of Geka coupling to air plug coupling

1/2″ Geka coupling test connection

Other sizes and segmentations available at request.

|

Ordering Information |

| Art.-Nr. | Produktbezeichnung | Eigenschaften | LxBxH & Gewicht | |

2001800 |

Muffenprüfgerät 700 |

Arbeitsbereich / Workspace: 700 mm Aufbau: 3-teilig Betriebsüberdruck: 6,0 bar |

600 × 670 × 670 mm |

提供

|

2001803 |

Muffenprüfgerät 800 |

Arbeitsbereich / Workspace: 800 mm Aufbau: 3-teilig Betriebsüberdruck: 6,0 bar |

600 × 770 × 770 mm |

提供

|

2001805 |

Muffenprüfgerät 900 |

Arbeitsbereich / Workspace: 900 mm Aufbau: 3-teilig Betriebsüberdruck: 6,0 bar |

600 × 870 × 870 mm |

提供

|

2001807 |

Muffenprüfgerät 1000 |

Arbeitsbereich / Workspace: 1000 mm Aufbau: 3-teilig Betriebsüberdruck: 6,0 bar |

600 × 970 × 970 mm |

提供

|

2001809 |

Muffenprüfgerät 1200 |

Arbeitsbereich / Workspace: 1200 mm Aufbau: 3-teilig Betriebsüberdruck: 6,0 bar |

600 × 1170 × 1170 mm |

提供

|

2001811 |

Muffenprüfgerät 1300 |

Arbeitsbereich / Workspace: 1300 mm Aufbau: 3-teilig Betriebsüberdruck: 6,0 bar |

600 × 1270 × 1270 mm |

提供

|

2001813 |

Muffenprüfgerät 1400 |

Arbeitsbereich / Workspace: 1400 mm Aufbau: 3-teilig Betriebsüberdruck: 6,0 bar |

600 × 1370 × 1370 mm |

提供

|

2001815 |

Muffenprüfgerät 1600 |

Arbeitsbereich / Workspace: 1600 mm Aufbau: 4-teilig Betriebsüberdruck: 6,0 bar |

600 × 1570 × 1570 mm |

提供

|

2001817 |

Muffenprüfgerät 1800 |

Arbeitsbereich / Workspace: 1800 mm Aufbau: 4-teilig Betriebsüberdruck: 6,0 bar |

600 × 1770 × 1770 mm |

提供

|

| You may also like… |

| Terms and conditions Cookies and Internet advertising About us Contact us |

Stay up to date

subscribe newsletter

|

How to find us

Hier erreichst du uns

Telphone:025-86618785

Email:nanjing@weltpure.com

Addr:江苏省南京市江北新区雨合路6号漫城软件园C座16-19层 |